How to Cut Costs and Increase Productivity with a Hydrogen Compressor

Hydrogen compressors can be a great way to reduce costs and increase productivity! However, it is important to consider all aspects of the system before implementation. To get the most out of your hydrogen compressor , there are several key steps that need to be taken. (First,) you'll want to examine your current processes and determine where improvements could be made. Then, identify any potential risks associated with introducing a hydrogen-powered system into your operations. Once you have an understanding of what needs to improve, it's time to start thinking about the cost savings associated with such a system. Many businesses underestimate the potential benefits that come from investing in efficient machinery. Make sure you look at both short and long term gains when calculating how much money switching over will save you in the long run! Next, (you'll need) to consider how easy it would be for your team members to use the new equipment and if they are properly trained on how to do so safely and effectively. It's also important that everyone understands why switching over is beneficial for their jobs as well as the company as a whole. This

Transport and Storage of Hydrogen

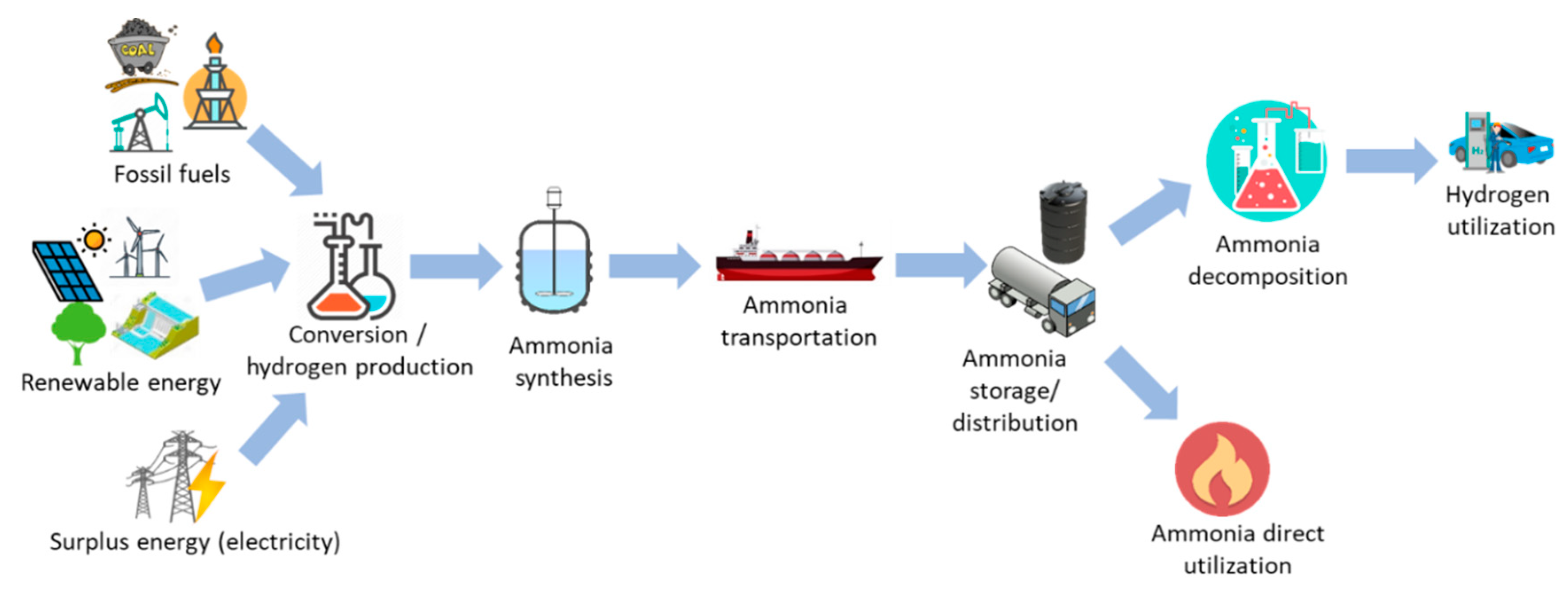

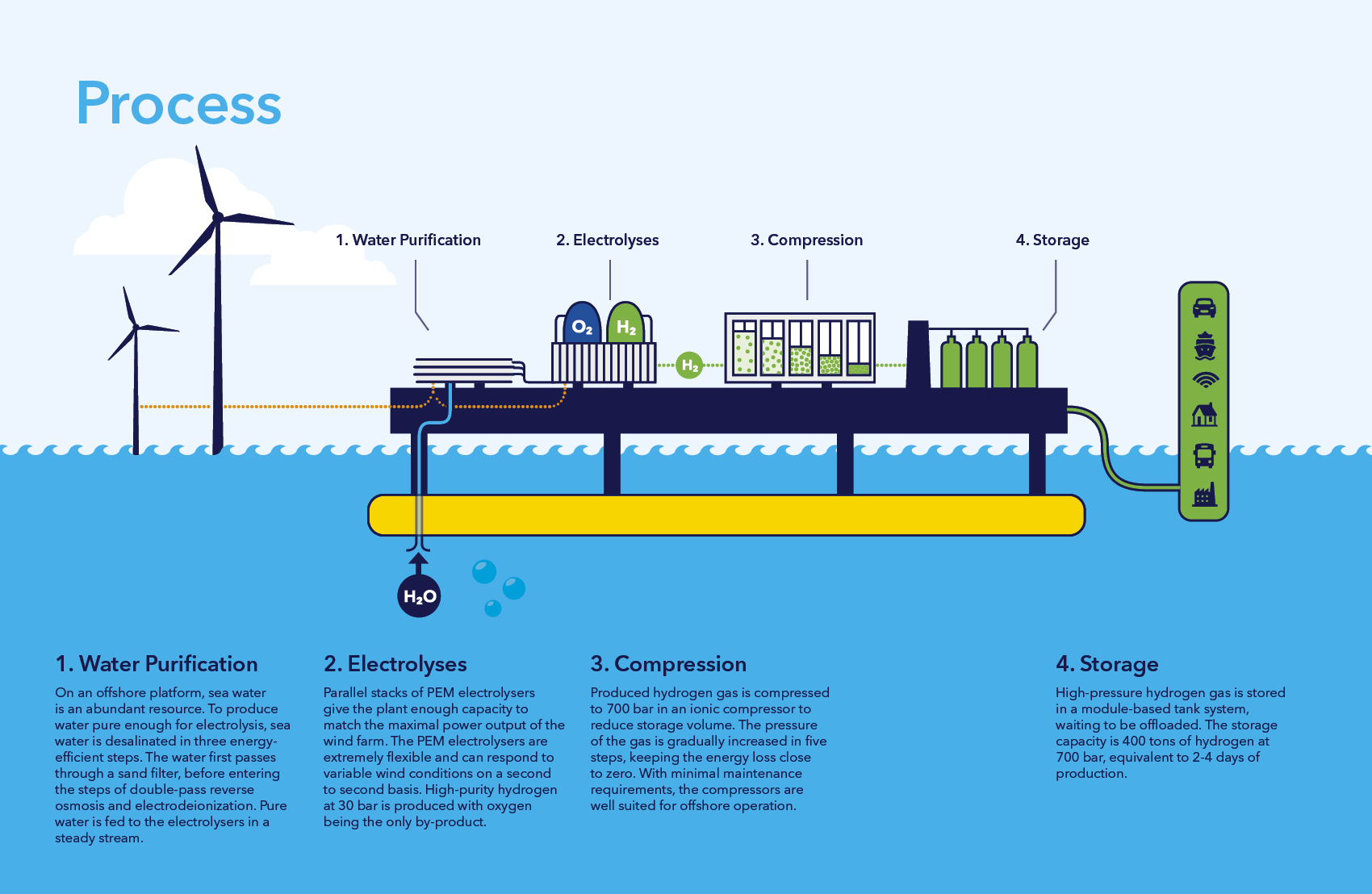

By francesco la porta and hidenobu usuda hydrogen presents opportunities as a clean energy source, either used as storage or as fuel in mobility, or as a feedstock in refineries and petrochemical processes. But there are many challenges to overcome, many of which revolve around the cost-effectiveness and reliability of hydrogen storage and transportation technology. Kawasaki heavy industries (khi) recently conducted a pilot study on hydrogen transportation. A new khi carrier transported hydrogen 9,000 km from the eastern coast of australia to kobe, japan. Of the many challenges examined during the sea voyage, the most vital was testing the atlas copco gas and process centrifugal compressor for boil off gas (bog) that ensures hydrogen remains chilled at -253° c in liquid form. Efficient Compression of Hydrogen With Diaphragm Compressors Sunfire gmbh, one of the ten most innovative energy companies worldwide, develops solutions for the production of hydrogen. When it comes to compressing the combustible gas, sunfire trusts the powerful compressors of mehrer compression gmbh. Read reference to ensure that the refuelling of fuel cell vehicles (tank pressures of 350 bar for buses, trucks, industrial trucks or 700 bar for cars) can be carried out quickly and energy-efficiently, hydrogen is cascaded from

Hydrogen Compressors: A Few Technical Challenges

S&s technical can assist with most hydrogen compressor applications. Whether you need a small oil-free process compressor package or a large, 1000 bar loading compressor package, we can provide a solution. Along with our line of blackmer oil-free recip compressors, we have also aligned with howden compressors to be able to offer the some of the world’s largest oil-free diaphragm compressors, ideal for high pressure hydrogen loading applications. Our design and engineering teams will provide a custom solution to fit your specific compression needs. We offer full turn-key packaged systems, system integration and start-up/commissioning support services to ensure project success. Hydrogen has gained significant attention in recent years as a clean and sustainable energy source, with the potential to revolutionize the energy industry. However, one of the challenges associated with hydrogen as an energy source is its storage and transportation. Hydrogen is a highly compressible gas, making it difficult to store and transport in its natural state. The study presents different varieties of hydrogen tanks that are used for the storage and transportation of hydrogen gas. The methods for compressing hydrogen are described, with a focus on their advantages and disadvantages. The study concludes by comparing different methods for

Hydrogen Compressors for Hydrogen Fueling Stations

Pdc machines & kpcl enter agreement for hydrogen compression in india pdc machines, a global supplier of diaphragm compression systems and hydrogen compressors for hydrogen refueling stations, has entered into an agreement with kirloskar pneumatic company limited (kpcl). Prominent in the air, refrigeration and gas compression business in india, to offer diaphragm compressors for various industries and applications throughout india. The agreement was executed in response to emerging hydrogen compression opportunities in india, where focus has been shifting steadily towards hydrogen for its decarbonization potential. Major government investment in green hydrogen is expected to continue in india through the rest of this decade. Hydrogen is increasingly used as a fuel in transportation because of its high energy density and environmental sustainability. Hydrogen delivery to fuel stations and vehicle fueling require a variety of different compression solutions. Burckhardt compression is one of the global market leaders in the field of reciprocating compressors. Its compressor systems are used in the upstream oil & gas, gas transport and storage, refinery, chemical, petrochemical and industrial gas sectors. We offer oil-free high-pressure compressor systems maintaining hydrogen quality according to sae j-2719. Haskel’s comprehensive support and maintenance packages offer peace of mind.

2 Hydrogen Compression Technologies

Our reciprocating compressor technologies are in action all over the globe, frequently delivered to api standards. They are proving vital in all gas processing including hydrogen in the mobility, industry and energy sectors through the respective production, transmission and distribution phases where safety remains paramount. Today’s available technologies and local circumstances in all geographies create new situations where howden’s compression can play a role. To help our customers reach their sustainability goals, howden designs relevant compression solutions designed to integrate large scales infrastructure applications to increase energy & production efficiency and minimize carbon emissions. Working in tandem with our customers, our engineering dna and experience delivers the winning combination by creatively balancing technical specifications, interface requirements, ambient considerations and future operating conditions. Electrochemical hydrogen compression (ehc) delivers pure gas at pressure on demand, with additional features such as single stage compression, no moving parts, silent operation and dynamic (reversible) flow control and low sensitivity to input pressure. Fast kinetics of hydrogen hor/her benefit the pump rate capability at the catalyst interface on the impermeable membrane. Here, we developed superior proton conductivity properties in combination with minimal hydrogen back-diffusion characteristics, to be able to compress to pressures