S&s technical can assist with most hydrogen compressor applications. Whether you need a small oil-free process compressor package or a large, 1000 bar loading compressor package, we can provide a solution. Along with our line of blackmer oil-free recip compressors, we have also aligned with howden compressors to be able to offer the some of the world’s largest oil-free diaphragm compressors, ideal for high pressure hydrogen loading applications. Our design and engineering teams will provide a custom solution to fit your specific compression needs.

We offer full turn-key packaged systems, system integration and start-up/commissioning support services to ensure project success.

We offer full turn-key packaged systems, system integration and start-up/commissioning support services to ensure project success.

Hydrogen has gained significant attention in recent years as a clean and sustainable energy source, with the potential to revolutionize the energy industry. However, one of the challenges associated with hydrogen as an energy source is its storage and transportation. Hydrogen is a highly compressible gas, making it difficult to store and transport in its natural state. The study presents different varieties of hydrogen tanks that are used for the storage and transportation of hydrogen gas. The methods for compressing hydrogen are described, with a focus on their advantages and disadvantages. The study concludes by comparing different methods for compressing hydrogen and discussing the factors that influence the choice of method for a specific application.

Advanced technologies to accelerate hydrogen deployment as an alternative source of energy.

Energy transition energy technology to help the industry advance on the path to net-zero

hydrogen technologies advanced technologies to accelerate hydrogen deployment

geothermal solutions experience and expertise to redefine possibilities in geothermal

carbon capture, utilization, and storage (ccus) integrated suite of solutions to capture, process, store, and monitor co2 emissions

emissions abatement solutions to monitor and reduce emissions from industrial operations

remote operations digital operations, monitoring and testing capabilities to serve critical industries

ai by bakerhughesc3. Ai enterprise-scale artificial intelligence for energy operations

liquefied natural gas industry leading solutions for long-term reliability, availability, and project success

industrial technology solutions to improve efficiency and uptime in processing and manufacturing industries.

Hydrogen Compressors in the Mobility Sector

Hydrogen is a key element in the green energy transition. Together with our partners, we are on a mission to deliver the most cost-efficient hydrogen compression package available. To allow wide use of hydrogen for mobility and trailer filling, equipment must evolve from small demonstration projects into industrialized and efficient solutions, enabling you to meet your total cost of ownership expectations. Reciprocating compressors play a key role in reaching this goal. At ariel and hoerbiger, we have the technology to enable the most economic and reliable package for high pressure hydrogen compression. Trailer filling transport and storage of hydrogen will be a central issue of the future hydrogen economy.

Demand for hydrogen is growing, for example to use it as future fuel for mobility and transport, green steel production, power generation, and process and district heating. According to the international energy agency , hydrogen demand is expected to increase fivefold from 2030 to 2070, with refinery as the only sector that decreases its demand.

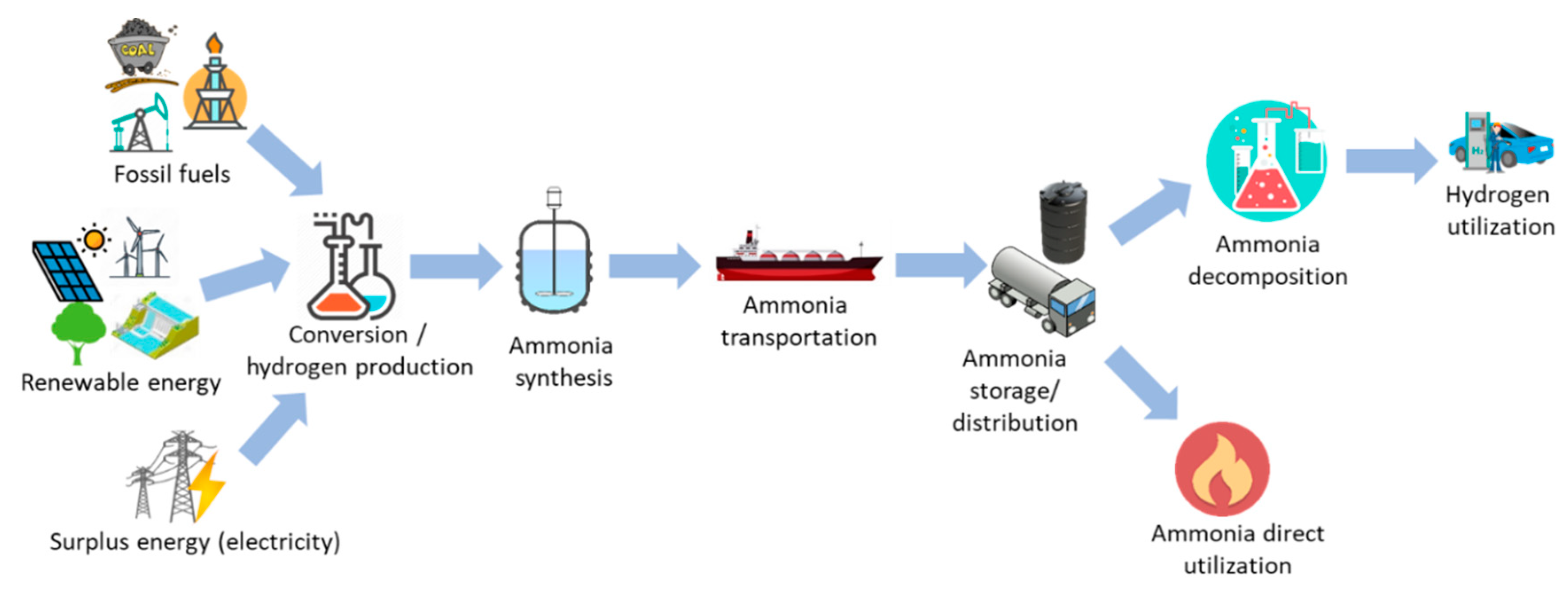

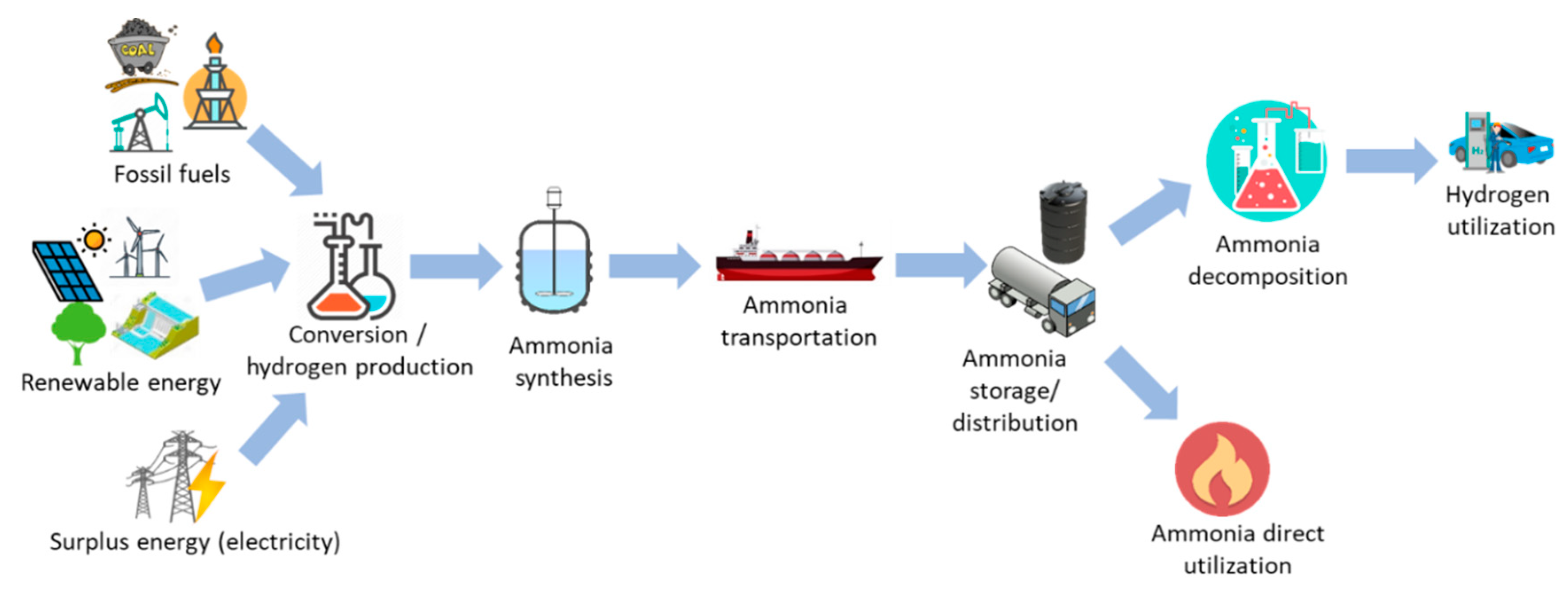

H2 can be transported as a gas by pipelines or in liquid form by ships, much like liquefied natural gas (lng). H2 can be transformed into electricity and methane to power homes and feed industry, and into fuels for cars, trucks, ships, and planes. H2 can enable renewables to provide an even greater contribution. Somewhere along the way, hydrogen must go through one of these, a gas compressor. H2 gas compressors have a different set of specifications because the hydrogen cell is so much smaller. Build standards are tighter. Before selecting a compressor, the operator should know the value of compression ratio, the heat of compression, duty cycle, packaging, location, and lubrication system.